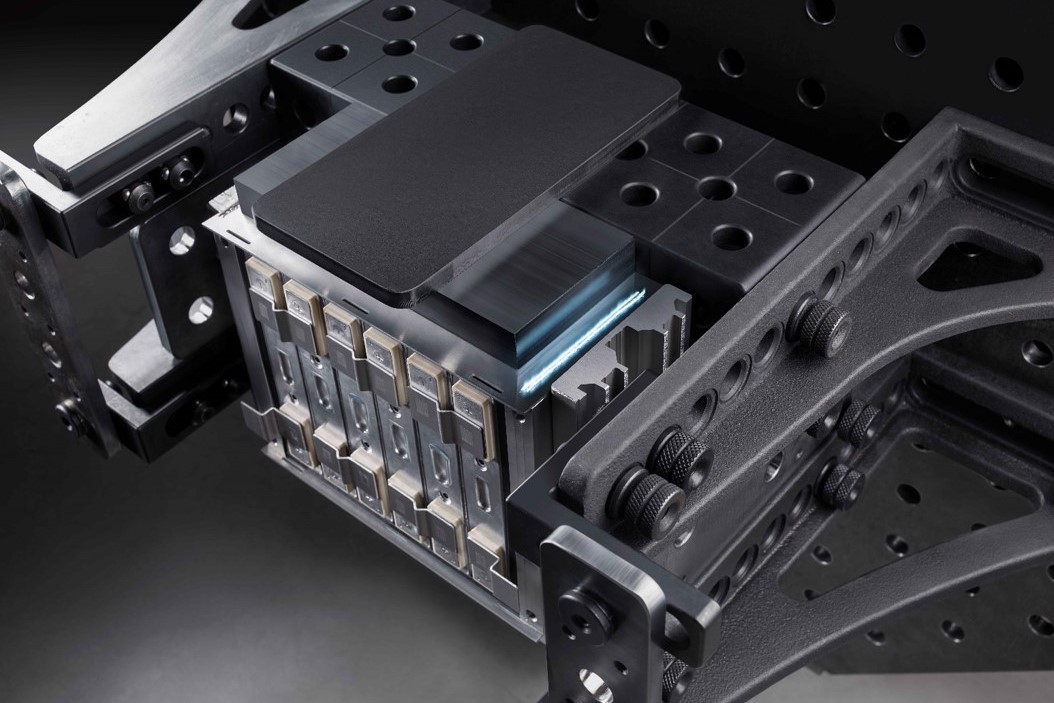

The aim of the development work was first to determine suitable laser welding parameters for the cell connection of the battery modules and to validate them by means of non-destructive testing (e.g. visual inspection and resistance measurements) and destructive testing (e.g. tensile testing and metallographic microsection examination). Subsequently, dummy but also active battery modules were welded. A suitable fixture was developed and set up for this purpose. Both pouch and prismatic battery cells were welded during the tests. The work carried out is intended to help build up expertise in the field of cell contacting. It is predicted that battery manufacturing will play a key role in automotive production in the long term.