These research partners and others are part of RWTH Aachen Campus, where a unique ecosystem with a comprehensive network of experts and modern research infrastructure is constantly growing. They include scientists from RWTH Aachen University, local affiliated institutes and Fraunhofer institutes, as well as SMEs and global players. Together, ideas are implemented faster – with reduced research and development costs at the same time.

The Innovation Factory offers the possibility of an iterative, agile development approach, which enables the rapid, interdisciplinary development of new products with the steps Ideation, Customer Focusing, Development, Prototyping and Industrialization. The Ramp-Up Factory provides the infrastructure for prototyping and investigating new production technologies for the development to industrialization steps. It is also possible to gain insights into how the subsequent series production of a component must be designed.

The center asks itself how the factory of tomorrow must be designed and how the factory planning processes must be designed faster and more effectively in order to build factories more efficiently. The Ramp-Up Factory can support the center’s concepts with concrete production knowledge and a practical “production factory” in order to be able to provide customers with the ideal factory design at the same time. Furthermore, the infrastructure of the Ramp-Up Factory can also serve as a reference factory for factory planning processes in the field of green- and brownfield.

The DFA is a central manufacturing environment on RWTH Aachen Campus, specialized in the development and production of components, up to the realization of products in small series in the field of cutting, forming and manual joining of metals. In cooperation with the Ramp-Up Factory, this already represents the beginning of value creation in component manufacturing and a certified welding operation.

The Tooling Academy is active in the business fields of consulting, digital solutions, further education and research. Here, the focus lies on future-proofing the tool manufacturing industry by linking science and industry. The cooperation with the Tooling Academy exists on the one hand in the area of machining production as a supplement to the Ramp-Up Factory portfolio and on the other hand the machines and prototypes of the Ramp-Up Factory also offer an interesting possibility to test the tools developed and manufactured by the Tooling Academy with us.

The Invention Center is the first point of contact for the rapid and customer-oriented implementation of innovative ideas on Campus Melaten. The Invention Center is an important partner of the Ramp-Up Factory, as it covers the first two process steps in the innovation cycle, namely ideation and customer focusing. Thus, the center is able to develop innovative ideas with potential customers and, through the support of the Ramp-Up Factory, to implement these ideas in the form of prototypes or investigations on machines, according to customer requirements.

The CSE pursues the goal of developing the necessary key technologies for the product creation processes of the future and testing them holistically, with model-based development of technical systems forming the basis for complete digitalization and automation. The CSE considers the “development” step in the innovation process, before the Ramp-Up Factory moves into practical implementation in prototyping. This collaboration with the Ramp-Up Factory is interesting for both sides and thus enables us to offer a holistic package.

ACAM bundles resources and access to the know-how of leading scientific and research institutions in the field of additive manufacturing. This covers the development of materials, the entire process chain, increasing productivity and reducing lead times. Here, the Ramp-Up Factory can serve ACAM on the one hand with 3D printing machines and other machines and manufacturing processes for the application and analysis of additively manufactured components. On the other hand, the Ramp-Up Factory can access ACAM’s significantly more extensive expertise in the field of additive manufacturing.

The GPMC enables companies to maximize their productivity by developing application-oriented methods and benefit-oriented tools for short-term decisions and long-term planning from the site level to the network level in order to make faster and better decisions in production. In doing so, the GPMC can not only help the Ramp-Up Factory accelerate decision-making processes in production, but the GPMC can develop new solutions based on the production and machines of the Ramp-Up Factory under real-world conditions.

Through its network of industry and research experts and through individual training programs, the CMA helps to master product- and process-induced complexity in an organization and to generate competitive advantages from successful complexity management. In doing so, the CMA can not only analyze the complexity in the customer’s processes, but can also implement it demonstratively with the infrastructure of the Ramp-Up Factory. The real challenges of implementing projects in the Ramp-Up Factory enable CMA to build up its own complexity management.

For the lightweight construction industry, target markets and applications for composite-based multi-material technologies are analyzed in order to identify economically relevant technology optimizations, in order to develop competitive innovations for economically highly relevant market segments, but also the appropriate partners for industrial implementation and establishment in the market. In this context, the Ramp-Up Factory is not only interested in the findings of the AZL, which can be implemented in its own approaches to lightweight construction. In addition, the Ramp-Up Factory can distinguish itself through the AZL as a contact point for the development of prototypes in the field of lightweight construction.

The CCI aims to provide interoperable, scalable, networked information systems for industrial use by bringing together competencies from industry and research to develop directly applicable industrial solutions in agile cooperation and to create an industrial ecosystem in which one can design, experience, understand, test and integrate innovative information systems. The Ramp-Up Factory provides the CCI with an infrastructure in which information can be exchanged and demonstratively examined on various manufacturing processes and machines.

The eLab provides an open infrastructure for research into electric vehicle production. This ranges from technology development and testing to finished prototypes. The available resources can be rented and used flexibly. Part of the Ramp-Up Factory is also located in the eLab and provides support in the areas of laser beam welding, prototype construction and testing. Together with the eLab, for example, the production chain from battery cell production to battery module production to battery pack production can be mapped (the last two steps together with the Ramp-Up Factory).

The E4TC collects suitable technologies for the implementation of digitization strategies on RWTH Aachen Campus, which are then used concretely and taught against this background. Here, the Ramp-Up Factory can not only use the expertise of the E4TC in the area of Industry 4.0 for the digitization of the Ramp-Up Factory itself. Together with the center, it offers its customers the opportunity to develop and implement Industrie 4.0 concepts for the further manufacture of the product whose prototype was manufactured in the Ramp-Up Factory.

The center aims to initiate a paradigm shift in today’s agriculture by sustainably supporting industrial agriculture with industrially established processes, methods and tools in the sense of a circular economy. It is interesting for the Ramp-Up Factory that innovations in this field inevitably lead to the testing of new technologies and machines in agriculture, for which the construction of prototypes for testing is necessary.

We have already successfully implemented a large number of projects – including publicly funded research projects or orders from industry. Here we present some of them to you.

NEXT e.GO Mobile

The e.GO Life electric city car from Next e.GO Mobile SE is one of the biggest success projects from the Production Engineering Cluster. After a highly iterative development process of only 3 years, series production started in Aachen.

PEM

In order to improve the quality of life within city centers while at the same time meeting the high mobility demands of the inhabitants, a new vehicle concept was developed in the Ramp-Up Factory, its components manufactured and the prototype vehicles assembled.

Anlauffabrik/Schulmann

Due to mechanical requirements, current solutions in industrial fixture construction are based on complete steel solutions, which undergo a complex design and manufacturing process. Additive processing of plastics is currently one of the most promising approaches in industrial prototyping for reducing the provisioning effort, such as production costs and time. In this way, fixtures can be designed and deployed that are tailored to the intended use and timeframe.

Team Sonnenwagen e.V

For the participation in the solar race World Solar Challenge across Australia, the student team Sonnenwagen Aachen e. V. developed and manufactured an ultra-light solar racing vehicle in the Ramp-Up Factory.

Anlauffabrik/Schulmann

The plastic-based additive manufacturing of tools, e.g. for use in sheet metal forming and injection molding, offers the potential to reduce high development and industrialization costs from components to complete vehicles. At the Laboratory for Machine Tools and Production Engineering (WZL) of RWTH Aachen University, this approach is being investigated on car body sheets, cell connectors in battery modules and interior components, among others.

Anlauffabrik/Schulmann u. TRUMPF

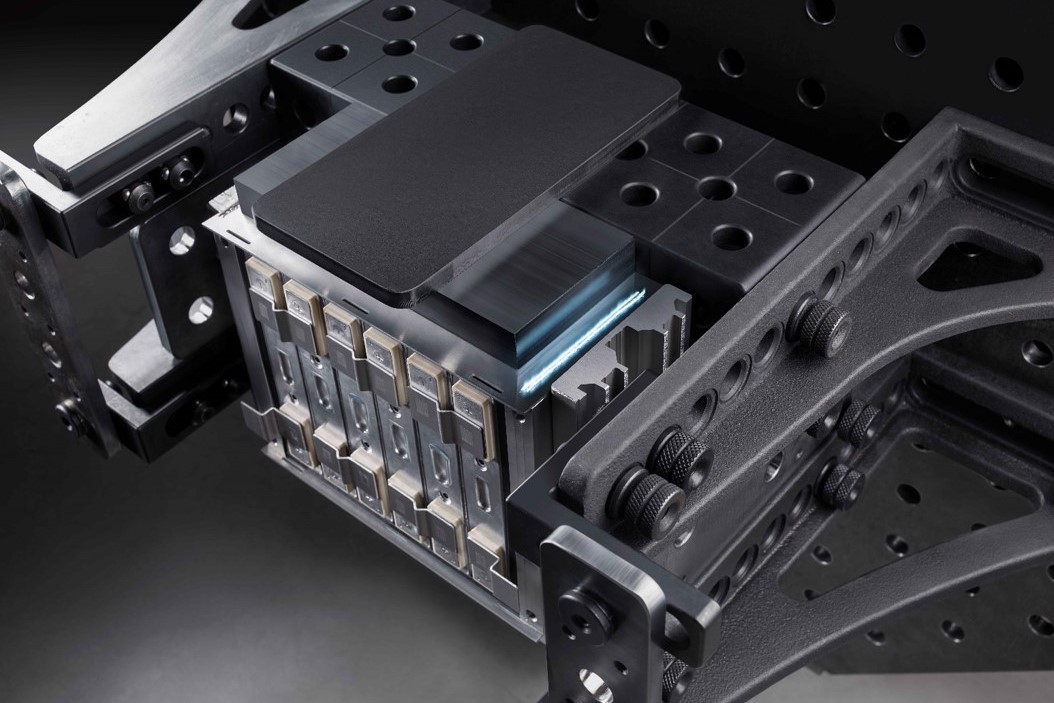

The battery storage system of an electric vehicle is largely responsible for its performance and cost structure. Many small battery cells are joined together to form battery modules, which are then joined together to form battery packs. In addition to joining the individual housings, the electrical contacts are also often joined by remote laser steel welding. In the new market of e-mobility in combination with remote laser beam welding, we have supported companies in entering this market.

Anlauffabrik/Schulmann

Anlauffabrik/Schulmann

Anlauffabrik/Schulmann

Anlauffabrik/Schulmann